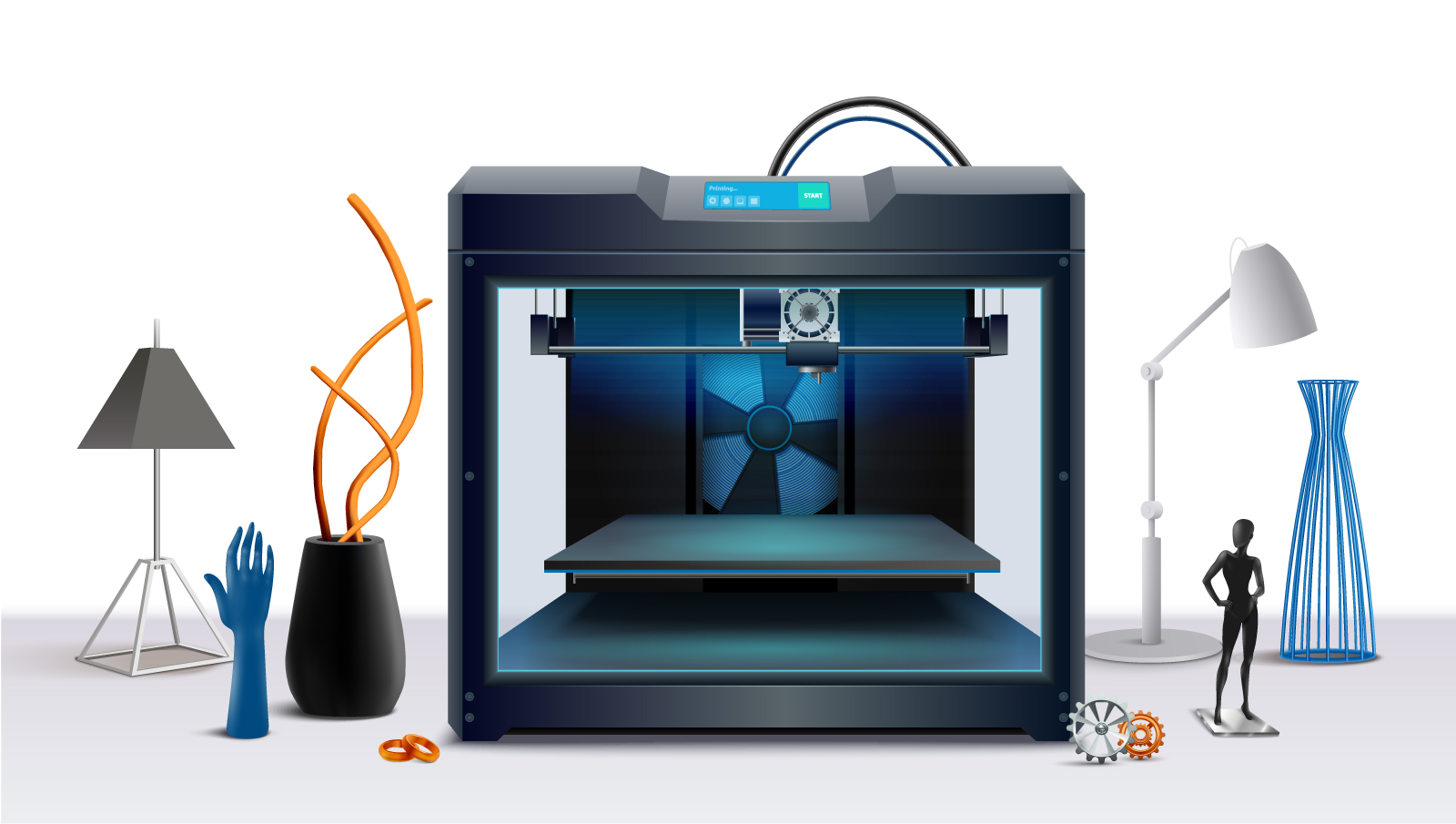

All You Need To Know About 3D Printing

Technological advancements are always on the rise. One such advancement is 3D technology. The buzz around this form of technology is vast. It has made headlines because it has been years in the making. Development of 3D technology has made many things possible. Changing the way people do things, and it is predicted to be even more prominent in the coming days. You should learn about 3D technology because it may soon affect your life. This could even assist you in your business.

What Is 3D Printing?

3D printing is an automated manufacturing process of creating a three-dimensional object by adding material instead of taking it away. The process runs based on a predesigned digital model. Because the material is added one layer after layer to form the three-dimensional object, it is commonly known as additive manufacturing. This printing was first introduced in the 1980s in the aerospace and automotive industries. It was used to create prototypes to be used in said industries rapidly. In the 90s, many industrial 3D printing companies emerged, but it was not until 2009 that 3D printing became commercially available to the public.

How Does 3D Printing Work?

3D printing is technically printing. It is more of an outgrowth of traditional printing. In traditional orienting, a layer of ink goes on to the material. It is quite light, and there is barely any noticeable height. 3D printing is an advancement of this because it extends that height by applying multiple layers.

3D printers use a variety of technologies, just like regular printing. The most common technology is stereolithography. It is a form of technology where a UV laser is shined into a vat of ultraviolet-sensitive photopolymer. This laser traces the object to be created on its surface. The polymer starts to solidify every time the beam touches it. This ‘prints’ the object layer by layer per a predesigned set of instructions.

Another form of technology is Fused Deposition Modeling (or FDM). It sees a thermoplastic material heated then pushed out through a nozzle. The nozzle deposits the molten thermoplastic layer by layer onto the platform. Each layer sticks onto the other, creating a three-dimensional object.

Selective Laser Sintering (or SLS)

Selective Laser Sintering (or SLS) is another form of technology in 3D printing. This type of tech sees the use of a laser beam that fuses powdered material. The first layer is evenly rolled onto the platform, then fused by a laser to the 3D model. The build platform then lowers to the width of one layer to roll in the next layer of powder. This process goes on a loop until the desired object is entirely created.

Additionally, some printers use Selective Laser Melting (or SLM). This sees the use of a high-intensity laser and metal powder. The small metal particles are melted together to create a solid piece of object that looks like it was made from a solid metal block.

What Is 3D Printing Good For?

3D printing is used for a lot of things. Whether you need a door stopper or even a new pair of frames for your glasses, 3D printing can do that. In the industrial world, 3D printing has aided many different industries. The healthcare and automotive industries have seen many benefits. 3D printing has enabled these industries to make products and put them on the market quickly. Instead of waiting for months, you will be looking at a few weeks. In the medical world, people are receiving 3D printed tissues and custom-built prostheses. 3D printing is also widely used in aerospace industries because it helps print small components required for prototypes and even working projects.

3D Printing and Businesses

3D printing could have a positive effect on businesses as well. One of the ways companies could use 3D printing is to customize their products. This is a genius way of ensuring that they stand out in a wash of competitors. People love personalized products, and if 3D printing can do that for the business, it would be beneficial. 3D printing can also help to develop prototypes for those in the manufacturing or engineering industries. The best way to impress investors is by creating prototypes for investors. It is cheaper than making the real thing. It is also faster.

If the business relies heavily on outsourcing products to succeed, 3D orienting could fix this. Having an in-house 3D orienting division ensures that outsourcing stops. The business will save a lot of money through 3D printing the items required. Also, it is more reliable and faster.

Because 3D printing is a new way of manufacturing goods, it will reduce the number of resources needed to begin. Additive manufacturing allows businesses to use an exact amount of resources, thus reducing the materials required to create the product. This type of manufacturing is affordable and even good for the environment.

You may also take a look at our packaging products: